- HOME

- ABOUT US

- PRODUCTS

- SERVICE

- APPLICATIONS

- NEWS

- ABOUT US 2

- PRODUCTS1

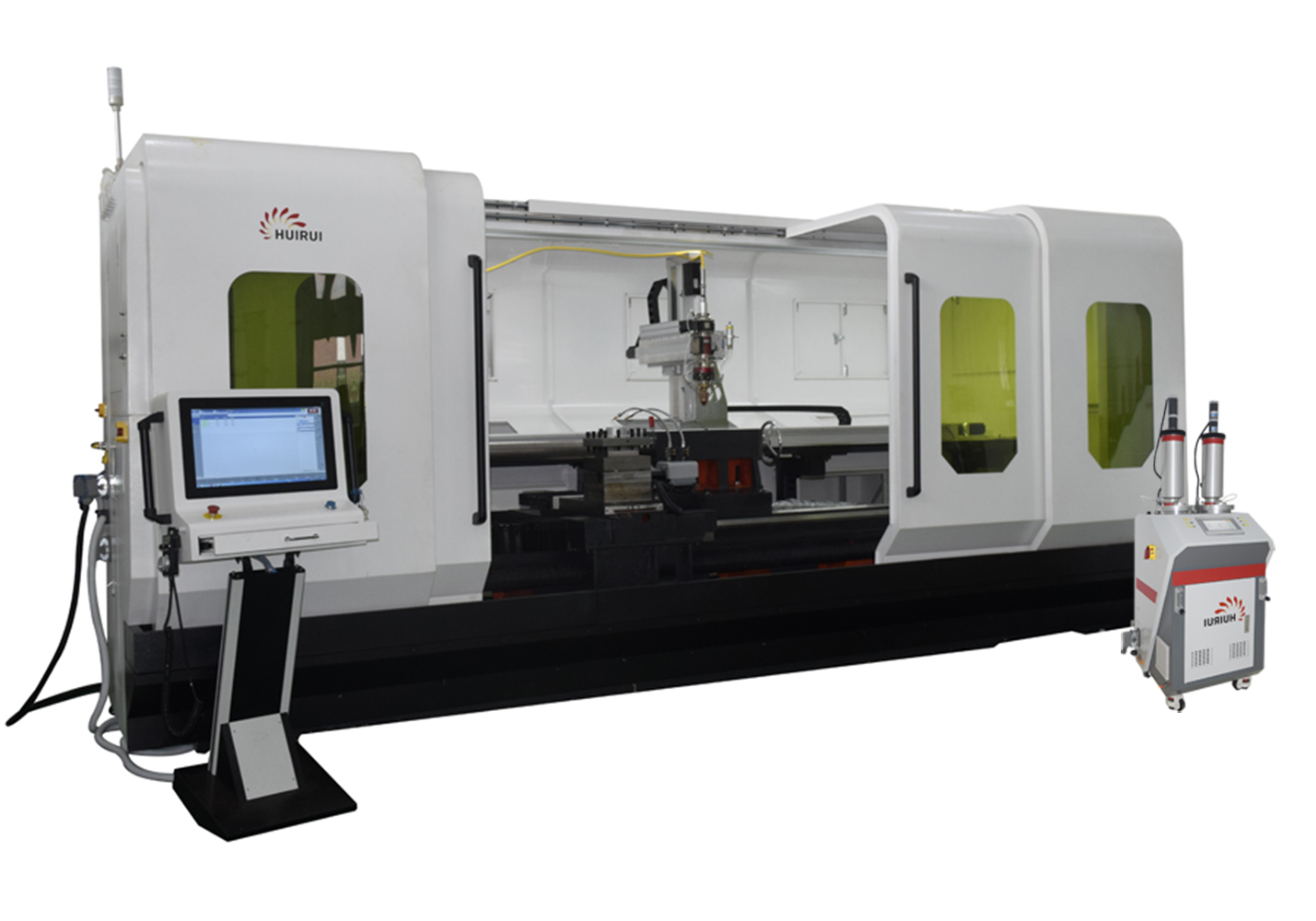

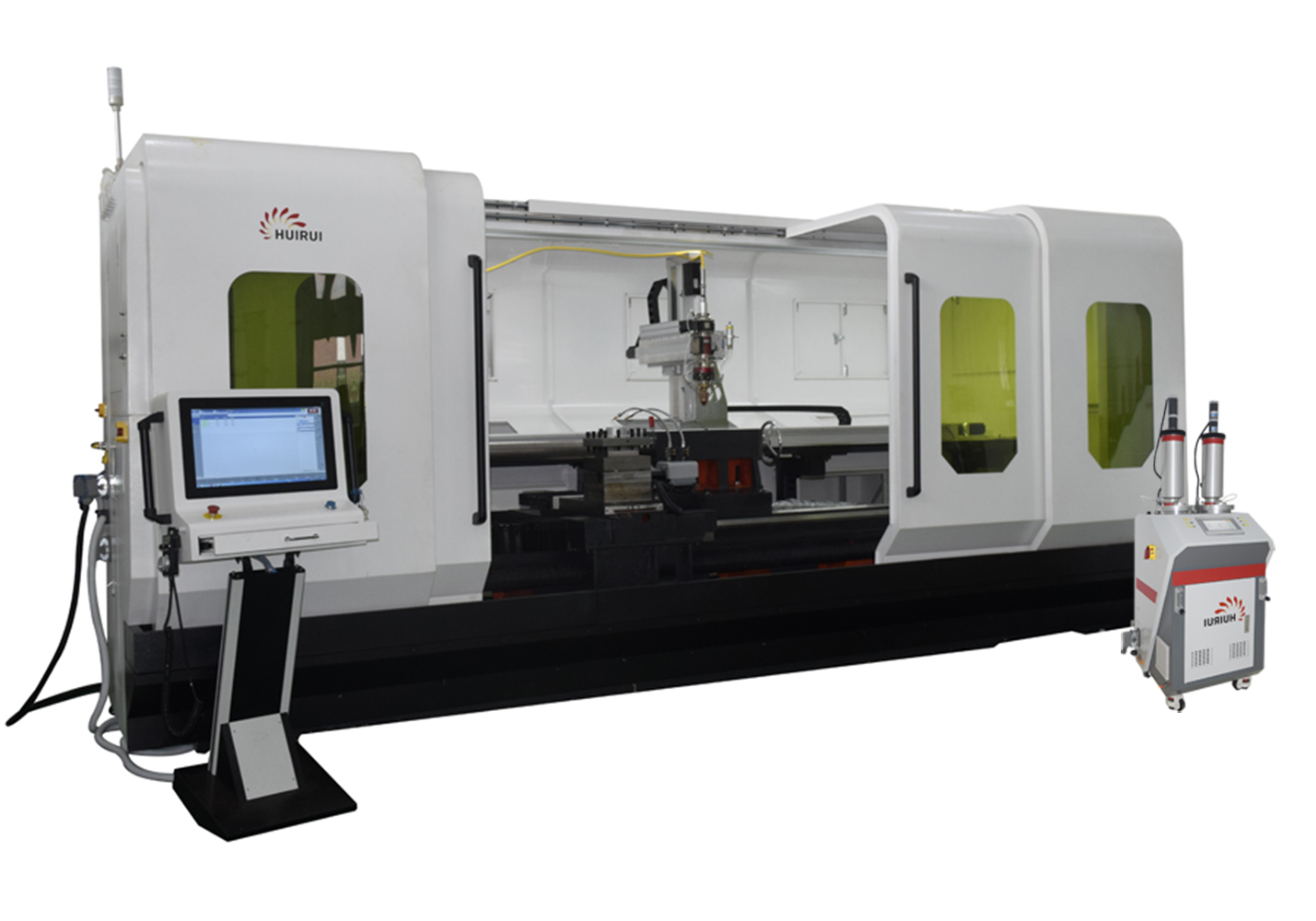

Ultra-high-speed cladding is an advanced environmentally-friendly remanufacturing technology. For the replacement of hard chrome-plated shaft parts, Huirui has successfully developed ultra-high-speed cladding equipment and process methods, which can realize integrated turning and cladding processing.

Based on all domestically produced equipment, Huirui has made breakthroughs in laser ultra-high-speed cladding technology independently researched and developed. Ultra-high-speed cladding is an advanced environmentally-friendly remanufacturing technology. For the replacement of hard chrome-plated shaft parts, Huirui has successfully developed ultra-high-speed cladding equipment and process methods, which can realize integrated turning and cladding processing.

Hybrid's hybrid

manufacturing combined with ultra-high-speed cladding can give full play to the

efficiency advantage, so that after the parts are positioned in one position,

the additive and the material can be combined to process the finished product

at one time, avoiding the relocation. Unnecessary coaxiality, round runout

error, greatly improve coating quality and production efficiency.

Device parameters

|

Laser |

Domestic solid-state laser |

|

Motion mechanism |

5-axis CNC |

|

Maximum swingable diameter |

640mm |

|

Processing length |

1.5m |

|

Repeatability |

0.012mm |

|

Layer thickness |

50–400μm |

|

Deposition efficiency |

Up to 500cm2/min |

|

Substrate dilution rate |

<1% |

Video 01 Ultra-high-speed laser cladding

The laser ultra-high speed cladding technology developed by Huirui has obtained a stable coating process that can be used in actual production through a series of tests and process optimization.

The conventional laser cladding powder is melted after entering the molten pool, the layer thickness is >500 μm, the laser scanning rate is <1 m/min, and the deposition surface efficiency is 10–50 cm2/min.

Ultra-high speed laser cladding process, the laser and powder flow fully interact, the powder is fully heated to the molten state before entering the molten pool, and the powder utilization rate is high.

The characteristics of the cladding

layer are as follows:

1. Can achieve a single layer thickness of 50–350μm

2. The deposition surface efficiency can reach up to 500cm2/min

3. Dilution rate <1%

Through further improvement and development of equipment and processes, Huirui Group has achieved ultra-high speed cladding on flat substrates.

Follow us on Wechat

E-Mail:info@huirui-tech.com

Address:No1 Ruixin Road, Jiangning District, Nanjing, JiangSu, China

地址:南京市江宁区瑞鑫路1号

NANJING HUIRUI PHOTOELECTRIC TECHNOLOGY CO., LTD.

Driving freedom of manufactUring

Landline:+86-25-86756108