- HOME

- ABOUT US

- PRODUCTS

- SERVICE

- APPLICATIONS

- NEWS

- ABOUT US 2

- PRODUCTS1

Adaptive conformal laser cladding Huirui independently develops products, maintains stable process quality and efficiency, shortens construction period, reduces costs for enterprises, and has matured into large-scale projects.

In laser cladding and laser remanufacturing

applications, the object to be processed is often an irregularly shaped

workpiece or has an uneven surface. The laser cladding nozzle needs to maintain

a constant distance from the workpiece surface in order to maintain stable

process quality. Therefore, in actual engineering applications, it often takes

a long time for programming, which affects the work efficiency and prolongs the

construction period. For the robot laser cladding system, it is mainly

reflected in the heavy robot teaching and calibration work. Under normal

circumstances, robot teaching is entirely dependent on manual operation, which

requires high operator experience and is prone to errors. It is a bottleneck in

achieving high-efficiency and high-precision laser cladding and repair

applications.

Software interface video

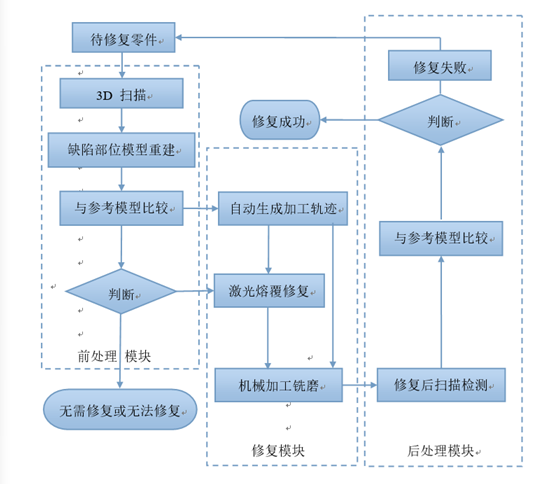

Adaptive conformal laser cladding is an effective method to solve the above problems. It mainly includes the following three basic steps:

1. On-line detection using sensors: sensors can be contact, machine vision, laser displacement, etc., and the corresponding relationship between the sensor measurement coordinate system and the robot laser cladding tool coordinate system must be established;

2. Automatic data processing: including data filtering, reconstruction, modeling, etc. Some applications also need to implement intelligent algorithms such as automatic model matching and defect identification;

3. Automatic path generation and process parameter

configuration: Based on the model established by automatic data processing,

layered slices, generation of filling trajectories, and automatic selection of

optimized process parameters based on defect types.

Structural diagram of laser cladding automatic repair

system based on 3D scanning

There are three typical application scenarios of adaptive conformal laser cladding:

1. Significantly reduce manual teaching, shorten programming time, and improve calibration accuracy;

2. Automatically establish the workpiece coordinate system or user coordinate system, so that the robot path generated by offline programming can be quickly and accurately applied to the workpiece, improving the production cycle; it can replace the conventional method of finding feature points, and can also solve some artificially undetectable scenes Problem location

3. With simple 3D scanning function, combined with automatic identification algorithm and slice path generation algorithm, fast defect localization and on-site adaptive repair can be achieved; although the general measurement accuracy is lower than the conventional 3D measurement system, it is sufficient for laser repair and has high efficiency High and low cost.

Follow us on Wechat

E-Mail:info@huirui-tech.com

Address:No1 Ruixin Road, Jiangning District, Nanjing, JiangSu, China

地址:南京市江宁区瑞鑫路1号

NANJING HUIRUI PHOTOELECTRIC TECHNOLOGY CO., LTD.

Driving freedom of manufactUring

Landline:+86-25-86756108