- HOME

- ABOUT US

- PRODUCTS

- SERVICE

- APPLICATIONS

- NEWS

- ABOUT US 2

- PRODUCTS1

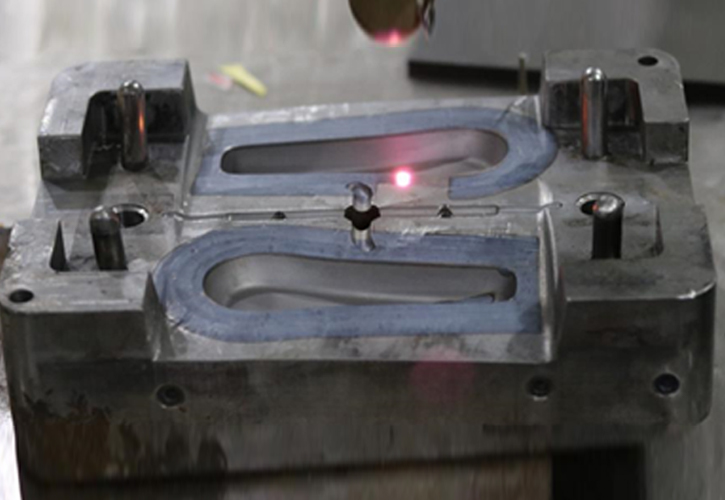

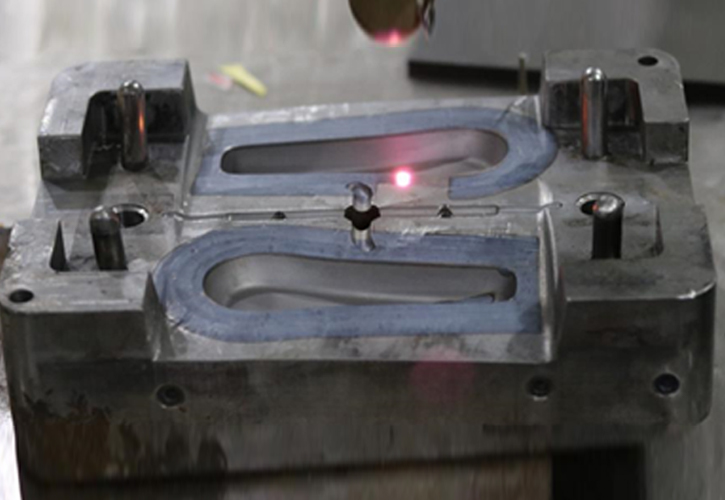

Mold is an important forming tool for manufacturing batch products. Wear and deformation are the main causes of damage. Laser quenching has high power density, fast cooling speed, and does not require cooling media such as water or oil. It is a clean and fast quenching technology. Compared with induction hardening, flame hardening and carburizing hardening, the laser hardened hardened layer is uniform, the hardness is 3 ~ 5HRC higher than that of ordinary induction hardening, the deformation of the workpiece is small, and it is difficult to cause cracking.

Repair Name: Die Quenching

Take H13 mold as an example, the hardness before quenching is 50HRC, the hardness after laser quenching is 58-65 HRC, and the hardening depth is 0.3-0.9mm.

Follow us on Wechat

E-Mail:info@huirui-tech.com

Address:No1 Ruixin Road, Jiangning District, Nanjing, JiangSu, China

地址:南京市江宁区瑞鑫路1号

NANJING HUIRUI PHOTOELECTRIC TECHNOLOGY CO., LTD.

Driving freedom of manufactUring

Landline:+86-25-86756108