- HOME

- ABOUT US

- PRODUCTS

- SERVICE

- APPLICATIONS

- NEWS

- ABOUT US 2

- PRODUCTS1

1. Technical background introduction

Traditional cleaning methods include mechanical cleaning

methods, chemical cleaning methods, and ultrasonic cleaning methods, and their

applications in environmental protection and high precision requirements are

greatly limited. In the 1980s, it was discovered that focusing high-energy

laser beams irradiated the contaminated parts of some articles, causing the

irradiated substances to vibrate, melt, evaporate, and burn a series of complex

physical and chemical processes, which could eventually make the pollutants It

is detached from the surface of the article to achieve the removal of surface

contaminants. This is laser cleaning. It gradually replaces the traditional

cleaning process in many fields with its many advantages, showing a broad

prospect for development.

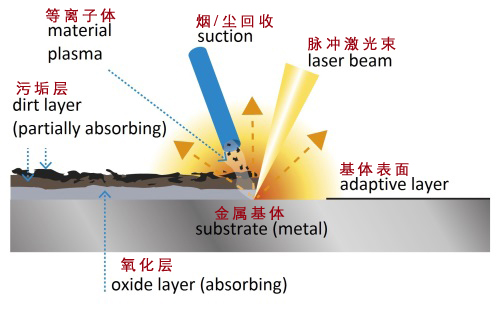

2.Laser cleaning working mechanism

Laser has the characteristics of high intensity, high

energy density, strong focus, and good directivity. Laser cleaning technology

uses three effects of laser pulse vibration, particle thermal expansion, molecular

photodecomposition or phase change to overcome pollution The binding force

between the substrate and the surface of the substrate enables the dirt to

escape from the surface and achieves the purpose of cleaning.

3. Advantages of laser cleaning technology

Since laser cleaning does not use any chemical solvents or other consumables, it is environmentally friendly, safe to operate, and has many advantages:

1. Green and environmentally friendly, without using any chemicals and cleaning fluids;

2. The cleaning waste is mainly solid powder with small volume and easy to collect and recycle;

3. The cleaning waste smoke is easy to absorb and handle, low noise, and no harm to human health;

4. Non-contact cleaning, no residual medium, no secondary pollution;

5. It can realize selective cleaning without damaging the substrate;

6. No working medium consumption, only electricity costs, low use and maintenance costs;

7. Easy to realize automation and reduce labor intensity;

8. Suitable for hard-to-reach areas or surfaces,

suitable for dangerous or dangerous environments.

|

Compare items |

Laser cleaning |

Chemical cleaning |

Mechanical polishing |

Dry ice cleaning |

Ultrasonic cleaning |

|

|

Cleaning method |

Laser, non-contact |

Chemical cleaning agent, contact |

Mechanical / Sandpaper, Contact |

Dry ice, non-contact |

Cleaning agent, contact |

|

|

Workpiece damage |

no damage |

Damage |

Damage |

no damage |

no damage |

|

|

Cleaning efficiency |

high |

low |

bottom |

in |

in |

|

|

Consumables |

Just power on |

Chemical cleaning agent |

Sandpaper, grinding wheel, whetstone, etc. |

dry ice |

Special cleaning fluid |

|

|

Cleaning effect |

Excellent, cleanliness |

Normally uneven |

Normally uneven |

Excellent and uneven |

Excellent, small clean area |

|

|

Precision cleaning |

Precise and controllable, high precision |

Uncontrollable, poor accuracy |

Uncontrollable, average accuracy |

Uncontrollable, poor accuracy |

Cannot specify range cleaning |

|

|

Safety / Environment |

Pollution-free |

Chemical pollution |

polluted environment |

Pollution-free |

Pollution-free |

|

|

Manual operation |

Simple operation, handheld or automated |

The process flow is complex and requires high operator requirements, and pollution prevention measures are required |

Consumption of manual labor is very hard, and pollution prevention measures are needed |

Simple operation, handheld or automated |

Simple operation, but requires manual consumables |

|

|

Cost input |

High first investment, no consumables, low maintenance costs |

Low first investment and high consumable costs |

High first investment and low labor cost of consumables |

High cost of medium supplies for the first time |

Low first investment and medium cost of supplies |

|

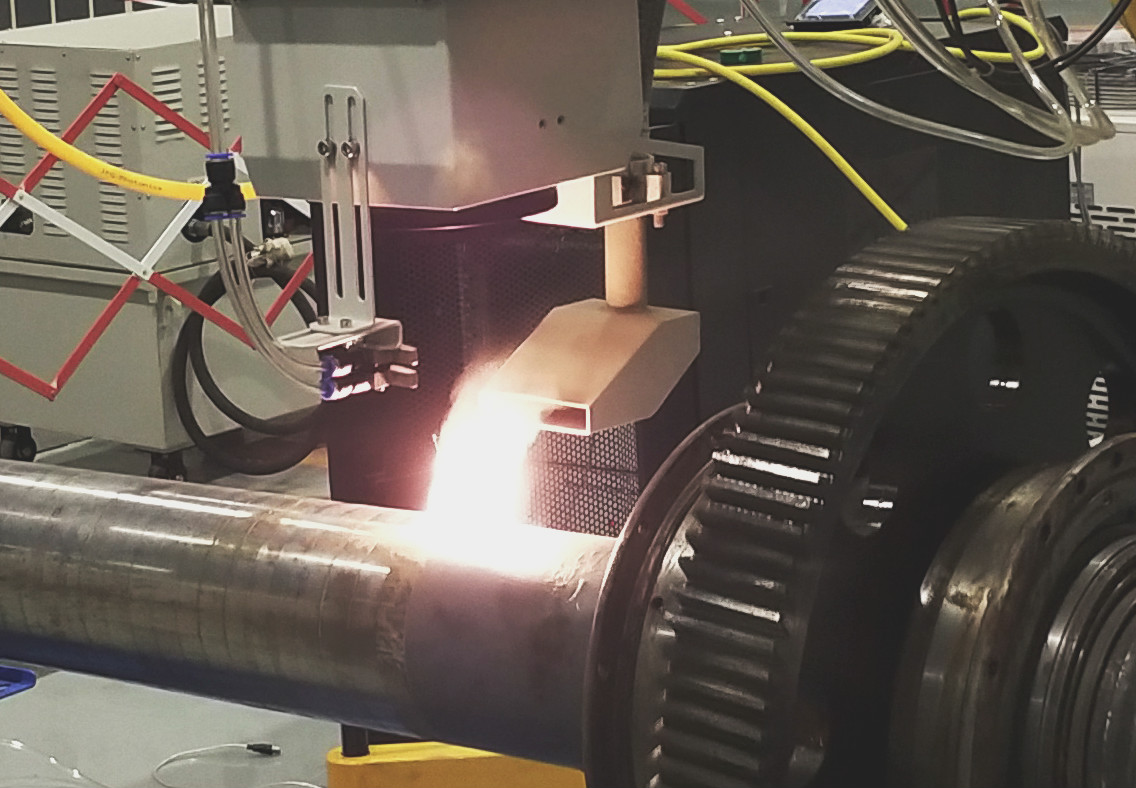

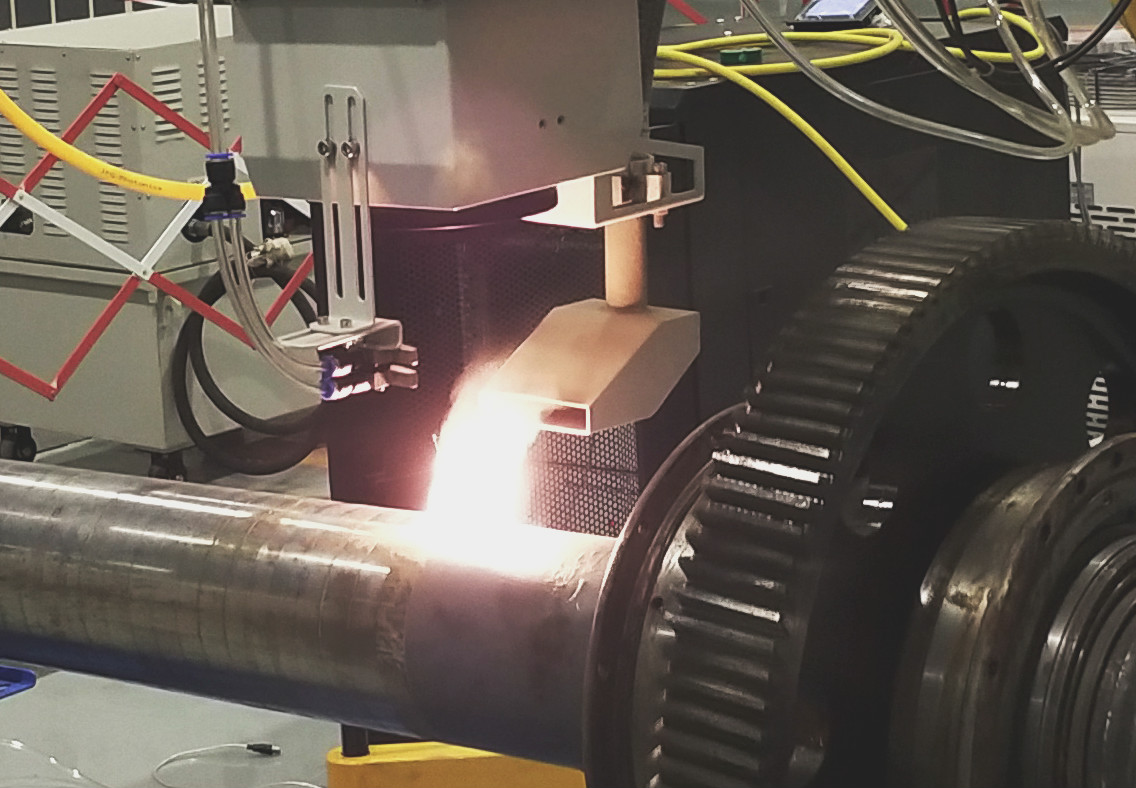

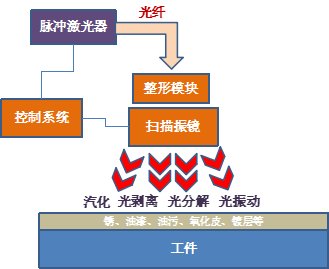

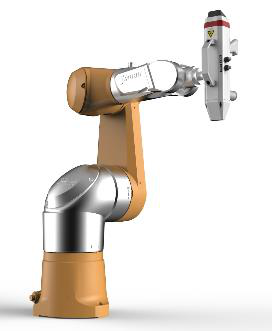

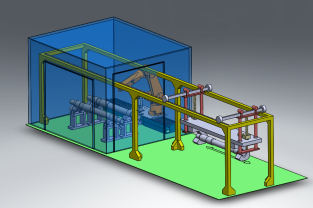

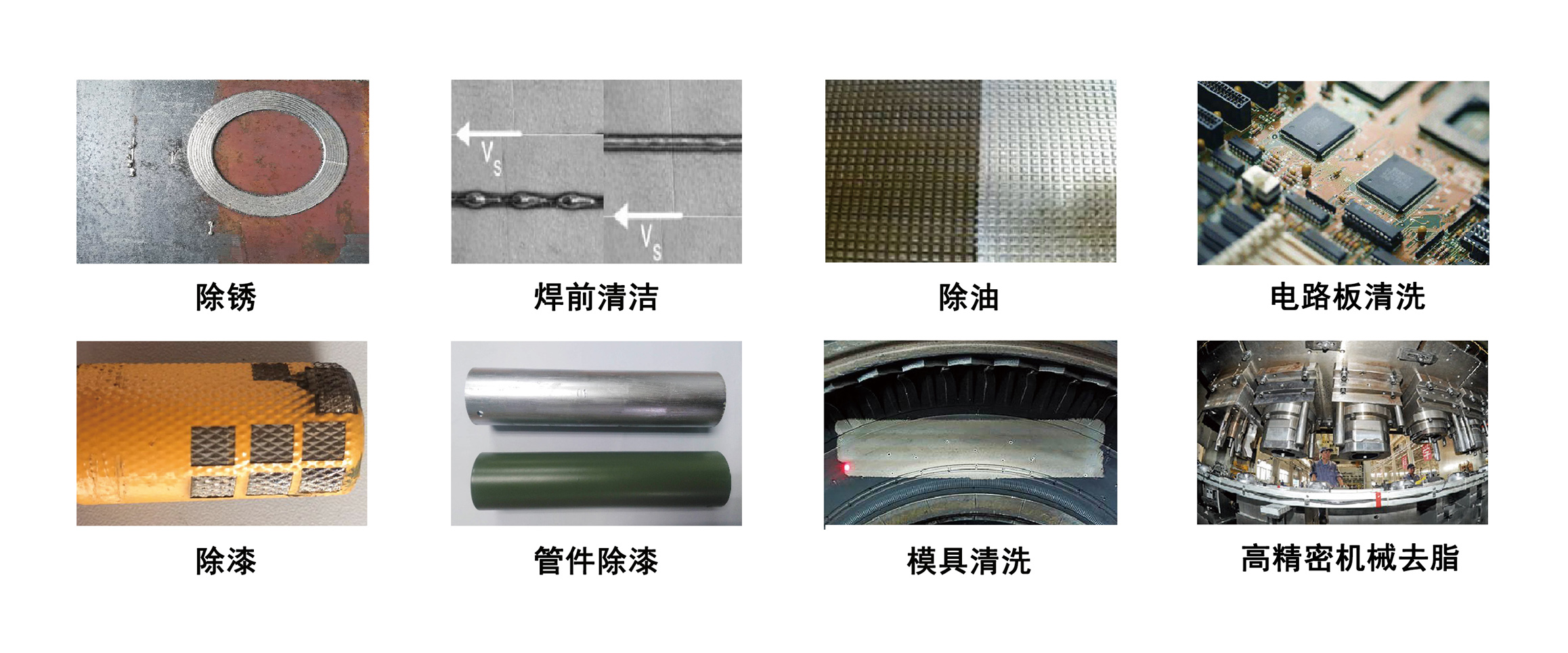

4. Huirui laser cleaning equipment and industry application

System principle

(1) Portable

(2) Mobile

(3) Integrated production line

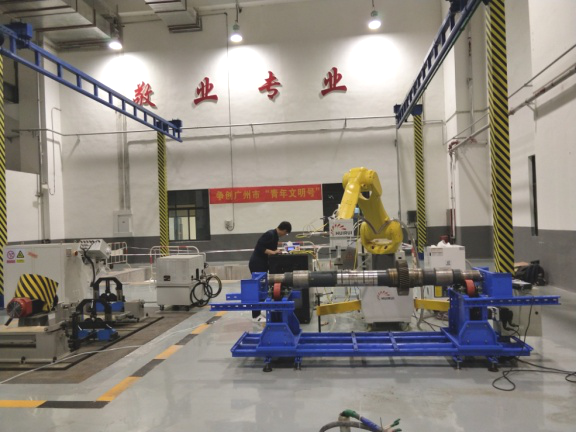

5. Industry applications

The

company's high-power laser cleaning system at the scene of an old domestic

subway company

Follow us on Wechat

E-Mail:info@huirui-tech.com

Address:No1 Ruixin Road, Jiangning District, Nanjing, JiangSu, China

地址:南京市江宁区瑞鑫路1号

NANJING HUIRUI PHOTOELECTRIC TECHNOLOGY CO., LTD.

Driving freedom of manufactUring

Landline:+86-25-86756108